Appliance Testing and Tagging Services in Adelaide

At Safe Test, we specialise in appliance testing and tagging services to ensure your workplace is compliant with safety regulations and minimises the risk of electrical hazards. Our certified technicians adhere to stringent Australian Standards, providing peace of mind for businesses of all sizes in Adelaide.

Why Choose Appliance Testing and Tagging?

Regular appliance testing helps extend the lifespan of your electrical devices and ensures they operate safely. Our services are essential for compliance with AS/NZS 3760:2022, helping you avoid costly fines and ensuring a safe environment for your staff.

Types of Appliances We Test:

- Power Tools: Drills, saws, and other power tools commonly used on job sites.

- Kitchen Equipment: Ovens, toasters, microwaves, and coffee machines used in commercial kitchens.

- Office Equipment: Computers, printers, and photocopiers found in corporate environments.

Our Comprehensive Testing Process:

- Visual Inspection: We thoroughly examine appliances for any visible damage or wear, such as bent plugs, frayed cords, and cracked casings.

- Electrical Testing: Using advanced Portable Appliance Testers (PAT), we assess earth continuity, lead polarity, and insulation resistance.

- Reporting: You’ll receive a detailed report documenting the test results, including whether each appliance passed or failed, along with any necessary recommendations.

Ensure compliance and safety with our reliable appliance testing services at Safe Test.

RCD Testing Services in Adelaide

Residual Current Device (RCD) Testing is vital for protecting your workplace from electric shock hazards. At Safe Test, we provide comprehensive RCD testing to ensure your safety switches are functioning correctly, as outlined in AS/NZS 3760:2022.

Why is RCD Testing Important?

RCDs are designed to trip when detecting even minor electrical faults, preventing severe accidents. Regular testing is essential to confirm that these devices operate effectively and meet safety standards.

Examples of RCD Applications:

- Commercial Kitchens: Protecting chefs and staff using multiple electrical appliances.

- Construction Sites: Ensuring worker safety around power tools and equipment.

- Industrial Machinery: Safeguarding operators in factories where heavy machinery is used.

Our RCD Testing Methodology:

- Push Button Test: We check if the switch trips as intended when the test button is pressed.

- RCD Trip Test: We simulate a power surge to assess the speed of the switch's response, ensuring it trips within the required time frame (under 40 milliseconds).

- Detailed Reporting: After testing, we provide a thorough report detailing the location of the RCD, its performance, and any recommendations for action.

Keep your workplace safe and compliant with our expert RCD testing services at Safe Test.

Microwave Leakage Testing Services in Adelaide

Microwave Leakage Testing is essential for ensuring the safety of your microwave appliances. At Safe Test, we conduct thorough testing in accordance with AS/NZS 60335.2.25:2020, which mandates annual checks for microwave radiation levels.

Why Conduct Microwave Leakage Testing?

All microwaves emit some level of radiation, but our goal is to determine whether the radiation levels are safe for use. Aging microwaves can increase health risks if not properly monitored.

Types of Microwaves We Test:

- Commercial Microwaves: Often used in restaurants and cafes for reheating food quickly.

- Household Microwaves: Common in residential kitchens for everyday cooking and reheating.

- Industrial Microwaves: Used in manufacturing processes for heating and curing materials.

Our 3-Step Microwave Testing Process:

- Visual Inspection: We assess the exterior of the microwave for any damage that may lead to increased leakage.

- Radiation Testing: We measure the radiation emitted during operation to ensure it remains within safe limits.

- Recording and Reporting: You will receive a detailed report for your records, indicating the results and reminding you when your next test is due.

Ensure the safety of your staff with our comprehensive microwave leakage testing services at Safe Test.

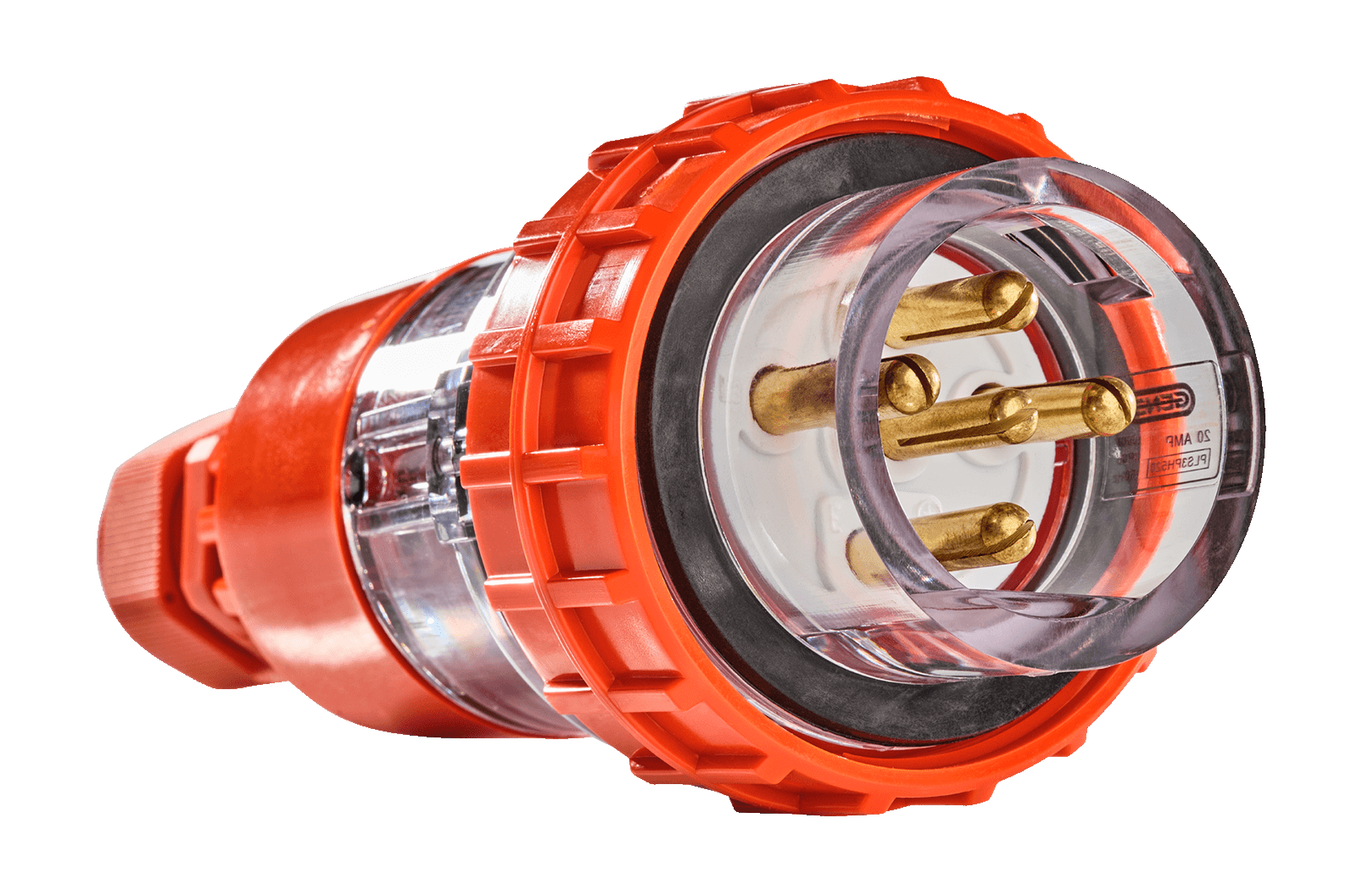

3 Phase Testing Services in Adelaide

At Safe Test, our 3 Phase Testing services are designed to maintain the efficiency and safety of your electrical systems. Regular testing is crucial for identifying potential issues in three-phase equipment that could lead to failures or safety concerns.

Why is 3 Phase Testing Necessary?

Properly functioning three-phase systems are vital for the reliable operation of large appliances and machinery. Compliance with AS/NZS 3760:2022 is essential for maintaining a safe work environment.

Examples of 3 Phase Equipment We Test:

- Industrial Machinery: Equipment like lathes, milling machines, and conveyor systems used in manufacturing.

- Commercial HVAC Systems: Large air conditioning units and heating systems that require three-phase power.

- Heavy Power Tools: Electric forklifts and other heavy machinery that operate on three-phase power.

Our 3 Phase Testing Process Includes:

- Visual Inspection: We thoroughly check your three-phase equipment for any signs of wear or damage that could affect performance.

- Electrical Testing: Our team conducts detailed electrical assessments to ensure the integrity and functionality of your systems.

- Comprehensive Reporting: You will receive a detailed report outlining the results of the tests, including recommendations for maintenance or repair.

Protect your investment and ensure compliance with our expert 3 Phase Testing services at Safe Test.